Don’t sweat the small stuff

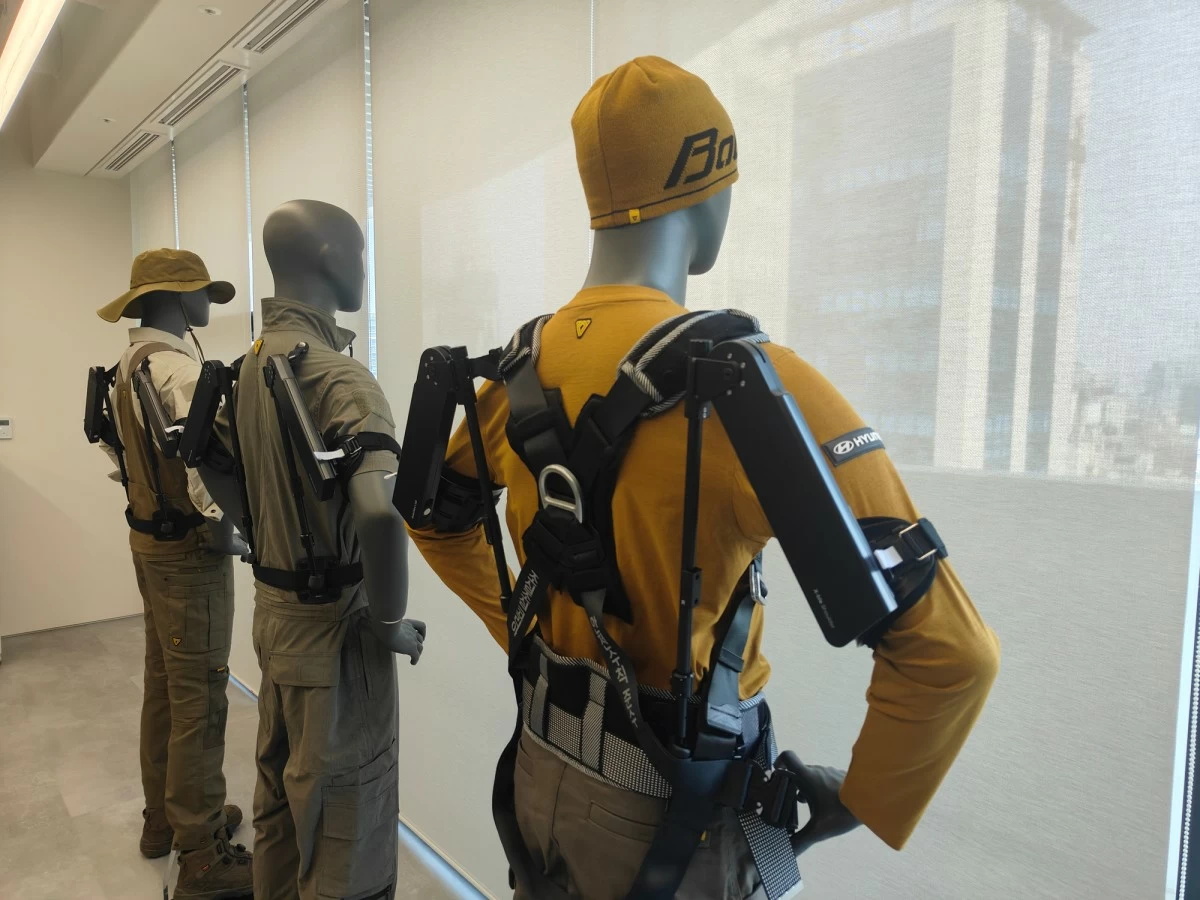

Hyundai may not be the first company that comes to mind when it comes to robotics. After all, most Filipinos still think it is just an automotive brand. However, over in South Korea, this company has grown to become one of the country’s largest and most influential, with interests not just in automotive but also in steel manufacture, shipbuilding, and even banking. With so many industries (including rival car company, Kia) under its belt, it should come as no surprise that this mega-corporation is also at the forefront of robotics and artificial intelligence in Korea. What they’re developing could soon make its way to a factory or office near you. A helping hand for mechanics Perhaps closest to one of their most globally renowned industries is their latest invention, designed to make life easier for the mechanics that work on Hyundai vehicles. **media[50796]** This innovation is the X-ble Shoulder wearable robot. This device can increase workers’ efficiency and reduce musculoskeletal injuries. Developed by Hyundai Motor and Kia’s Robotics LAB, it was designed for overhead work, augmenting the user’s upper arm muscle strength and reducing the strain and burden on muscles particularly when working in this position for long periods. It works by generating an assistive force through its muscle compensation module. Best of all, there’s no need for a motor or battery. It does all this through a non-powered torque generation structure. It uses carbon composite and wear-resistant materials, just like in high-end vehicles, making it high strength but lightweight. As a result, users enjoy reduced shoulder load by up to 60 percent and less anterior/lateral deltoid muscle strain by up to 30 percent, improving quality of life for workers. We were even encouraged to try it ourselves. It feels like simply putting on a tool vest. When arms are raised, it feels like a colleague is simply helping to hold your arms up. Movements still feel natural and are, in fact, much lighter. **media[50792]** Though initially designed for mechanics, it’s evident this wearable robot has applications in many other fields, with construction, shipbuilding, aviation, and agriculture among those envisioned. Hyundai is already deploying this innovation in select automotive workshops as well as testing it in vineyards in rural Korea. Perhaps soon, we might see this in Hyundai and Kia workshop in the Philippines. Automating EV charging EV charging may not be a pressing concern here, but in more electrified countries, particularly like Korea, the act of plugging in your EV to charge can take up valuable time. As such, Hyundai has also sought to automate this simple task. Yet another one of their creations is the artificial intelligence (AI)-based electric vehicle (EV) automatic charging robots (ACRs). These robots are designed to find a car’s charging port, open the flap, and plug in the charger. By using cameras governed by AI technology, the robot can recognize the vehicle, find the flap covering the charging port, open it, then guide the charging cable toward the plug and initiate charging. **media[50794]** This act is one of the first steps toward automating the EV charging process. By doing so, EVs can be charged right up until their batteries are full and then disconnected once done so the robot can move on to the next vehicle that needs charging, saving on charging infrastructure, and power. Hyundai demonstrated a stationary model, however the goal is to make these robots mobile one day. These ACRs are already deployed at the Incheon International Airport Corporation (IIAC) with plans to expand to other airports, seaports, and railways. Robotic coffee delivery Fetching coffee is a task often imposed on interns and executive assistants, but Hyundai thinks this task can be automated too. That’s why they built DAL-e Delivery, a robot designed to revolutionize indoor autonomous delivery services. Coffee is the perfect testbed, being something highly in-demand in any office, but easy to spill if handled improperly. DAL-e Delivery was invented to provide reliable F&B and parcel dispatch services. **media[50795]** DAL-e Delivery is a podium-shaped robot with rounded corners. It can rotate on its own axis and travel up to just 1.2 meters per second. It’s equipped with the same autonomous driving technology in Hyundai’s cars to prevent it from bumping into walls and other people. Best of all, it was also programmed to use elevators, able to find its assigned elevator, know where to ‘stand’ to give other people room, as well as communicate with the elevator via the network to select a floor. Its services are simply called up via a mobile app. It can safely transport 16 cups of coffee or packages weighing as much as 10 kg. Finally, it uses a camera and facial recognition to only open its doors when it identifies the correct recipient. Let the machines do it These may all seem trivial tasks to many, but automating these simple matters are one of Hyundai’s solutions to making humans more productive at their assigned tasks. The goal is not to replace people with machines, but save their time by letting machines worry about the little things, so they can keep their attention on the bigger priorities. Wouldn’t it be nice not to get up from your seat just to get a coffee? Perhaps one day, that will be possible.